Hedi Bessrour joins Emil Otto’s international sales team

We are expanding our international sales team with the signing of Hedi Bessrour. Bessrour has been appointed as the new International Sales Manager.

Corrosion protection for metals

With our rust protection oil VO, you can reliably protect your machines and vehicles against rust and moisture, ideal for agriculture, construction and maritime applications.

Emil Otto presents special flux for nickel and nitinol – EO-M-026

Our EO-M-026 flux is a ready-to-use, highly concentrated special flux that has been specifically developed for soldering and tinning processes involving nickel alloys, including nitinol.

Emil Otto presents optimized FLUX REMOVER EO-RA-007 (+)

The FLUX-REMOVER EO-RA-007(+) from Emil Otto is a powerful and efficient electronic cleaner specifically developed for manual cleaning of electronic assemblies and other sensitive surfaces.

High-performance protective fluid for selective soldering nozzles

The EO-NOZZLE-PROTECT 1.0 fluid from Emil Otto GmbH is a specially developed protective fluid for soldering nozzles in selective soldering applications.

Cleaning solar panels on roofs and balconies

Why is it important to clean pollen from solar modules on roofs or balconies?

Fluxes for reliable cable assembly

Why do fluxes play just as important a role in cable assembly as in the rest of electronics production?

Secure and solid solder connections for applications with high vibration levels

In electronics, the reliability of soldered connections is crucial, especially in high-vibration environments.

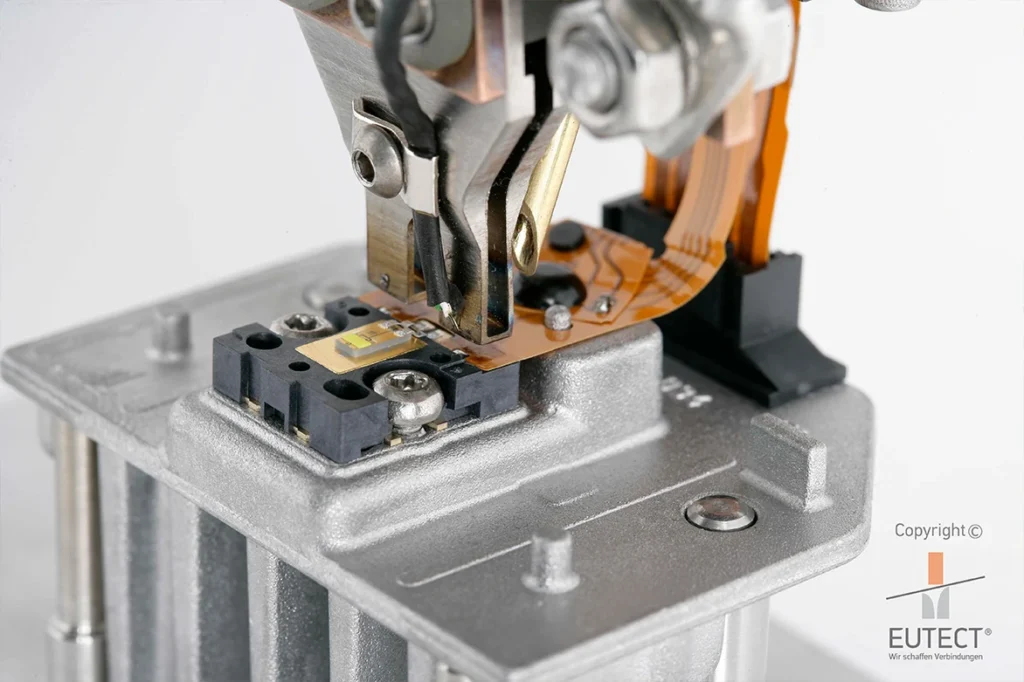

Emil Otto presents fluxes and gels for thermode soldering

Our new No Clean special fluxes HTW-48 and HTW-49 are fluxes for high-temperature applications in the soft soldering area, which are also available as flux gel. Both fluxes are suitable for thermode soldering as well as for cable assembly.

Soft soldering in pipeline construction

The ZINNIN GREEN I Sn100 soldering and tinning paste from Emil Otto is particularly well suited for soft soldering in pipeline construction and for soldering copper pipes and brass fittings.