Emil Otto launches new stencil cleaner

The German specialist for fluxes and cleaning agents for electronics production presents the new Etimol SW 22 CN stencil cleaner for the automated cleaning of SMT stencils. Due to the use of special solvents, the cleaner is not a hazardous product, which simplifies transport and storage.

Emil Otto launches further variants of the water-based flux EO-G-006

The Hessian flux specialist Emil Otto GmbH launched the water-based flux EO-G-006 back in 2023. This is a No Clean-Flux that is suitable for wave, manual and selective soldering of printed circuit boards. It contains organic, halogen-free, activating additives specially adapted to the soldering processes. This is followed by variants A, B and C with different levels of solids.

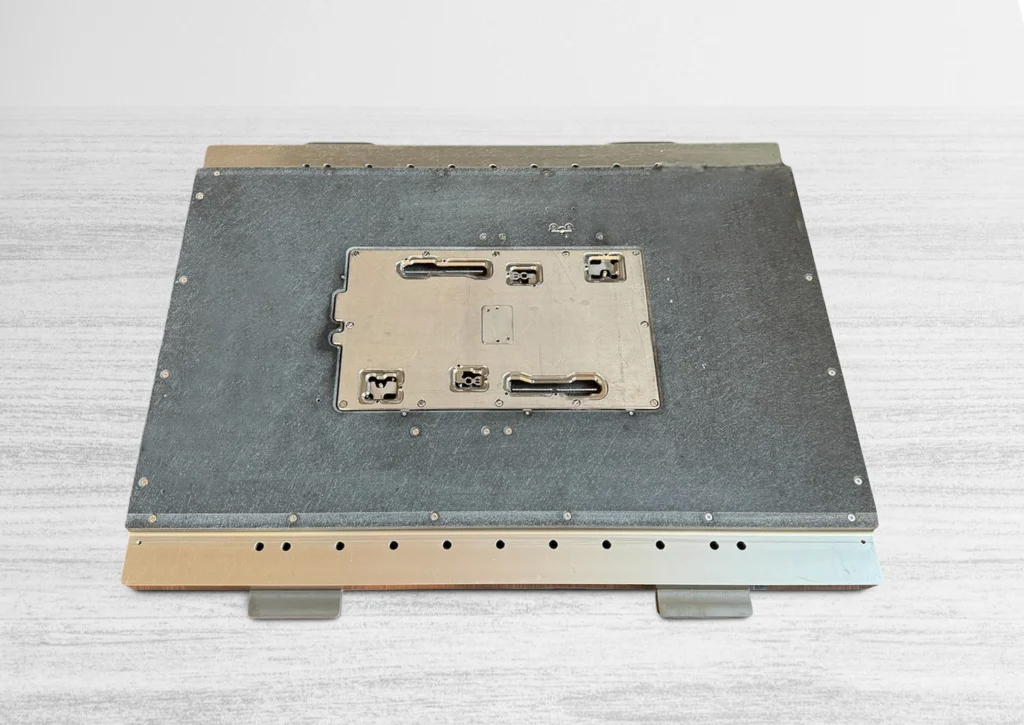

Emil Otto and Leutz Lötsysteme successfully test flux and cleaning agents

In a joint test procedure, Emil Otto GmbH and Leutz Lötsysteme GmbH have determined the effect of flux and cleaning agents on materials such as those used in workpiece carriers or coating frames. The aim was to determine how their material condition may change after the chemicals have been used and what effects result from this. The results should help to provide customers with even better advice when selecting consumables in the future.

Product group relating to the flux EO-B-016 is expanded

Emil Otto’s established alcohol-based flux EO-B-016, which can be used in wave, selective and hand soldering processes as well as in dip soldering and for strand tinning, has a solids content of 5%. Further A, B and C versions of the flux are now being launched by the German flux specialist with different solids content.

Emil Otto launches optimized machine cleaner Etimol SEM 12 RAA/NF in the market

With the new Etimol SEM 12 RAA/NF machine cleaner, Emil Otto is launching an optimized version of the established Etimol SEM 12 RAA cleaning agent. The cleaner is characterized by an improved cleaning effect and also leaves no sticky residue even if it has not been completely removed with a wipe.

Emil Otto shows sustainable practices

Companies in the chemical industry are legally obliged to follow guidelines that ensure sustainable action. However, Emil Otto is going one step further and uses the website https://living-sustainability.com/ to document the fact that ecological, social and economic action is an integral part of its corporate philosophy.

Emil Otto launches new flux SOLAR-FLUX EO-S-023 for the solar industry

With the new SOLAR-FLUX EO-S-023, flux specialist Emil Otto is further expanding its portfolio of fluxes for the manufacture of solar modules. The leading manufacturer of fluxes for the electronics and solar industry from Eltville in the German state of Hesse is once again presenting innovative solutions to further optimize processes in assembly and connection technology.

Gentle cleaning agents for solar modules

Photovoltaic modules must be cleaned regularly to ensure maximum performance. Dirt can block the sun’s light and therefore reduce power generation. However, care must be taken when cleaning, as the use of chemical cleaning agents carries a considerable risk of damage. Emil Otto GmbH has therefore developed gentle cleaning agents for solar modules.

In ‘agri-photovoltaics’, the cleaning of solar panels must be environmentally sustainable

The use of agricultural parks for energy production using solar technology is an innovative and sustainable solution that addresses the challenges of modern agriculture and energy production. However, the use of solar technology on agricultural land results in special requirements for cleaning agents that are used for cleaning solar panels.

Innovative cleaning agents support the cleaning of solar panels using drones

Emil Otto GmbH, a leading supplier of cleaning and soldering agents for the solar industry, has already launched a range of products for cleaning solar panels. These innovative cleaning media also support cleaning with drones and thereby significantly increase the efficiency and longevity of solar systems. At the same time, the effort required to clean solar panels is reduced.