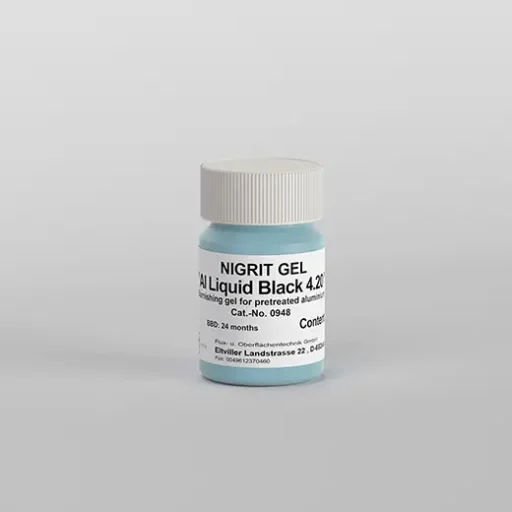

Black pickling and cold burnishing agent, viscous medium (gel) on acid basis, especially for freshly sanded aluminium (also for individual freshly sanded areas on aluminium surfaces)

| Appearance: | light blue gel |

Area of application:

The ready-to-use gel has been developed for precise direct dosing. With this gel, the workpiece to be treated can be wetted with pinpoint accuracy. The gel does not run, but acts exactly where it is applied. Components can be blackened on a workpiece that would otherwise have to be removed for burnishing.

Degreasing and inserting the parts:

Thorough degreasing of the parts is a prerequisite for uniform blackening.

Blackening effect:

Depending on the material, blackening occurs relatively quickly (approx. 5 – 30 sec. after application). Longer exposure times are possible, but should be determined by preliminary tests so that the workpiece to be treated is not damaged. Afterwards the spots or parts are cleaned with sufficient water and rubbed well dry with a clean cloth (rag). If NIGRIT GEL “Al Liquid Black 4.20” remains too long on the workpiece, loose oxides will accumulate on the surface, which have to be removed after the process (expediently with a root brush or similar).

If the darkening/blackening is not sufficiently dark, the burnishing process can be repeated after the material has been cleaned. In practice, it has been found that more than five burnishing passes hardly show any significant improvement. If an irregular coloration is noticeable after burnishing, this may be an indication of insufficient degreasing.